PHOTOVOLTAIC-THERMOELECTRIC (PV-TE) HYBRID MODULE WITH ACTIVE COOLING ELEMENT BY USING LABVIEW

Saturday, 27 April 2013

enGinEerinG daY

CONCLUSION

This day is the presentation day and be called as Engineering Day. All the final year student will present their project to the accesors. It a quit though day since that I have n my fiend have to be there at 8am until 5pm. I got Mdm Ziany and Sir Razak. Their question is a bit though and I almost drown by their questions and Alhamdulillah, I pass through it.

Wednesday, 17 April 2013

Tr0ubLe sHo0tinG

OBJECTIVE

METHOD

- To study the circuit

- To troubleshoot the circuit

- To observe the output graph

METHOD

- Combine all the circuit and connect to the DAQ and LabVIEW

- The step is same with before

- Troubleshoot the circuit to find problems that occurs

- The output (graph) being observed and save for further references

RESULT

Figure 1: Circuit Connection

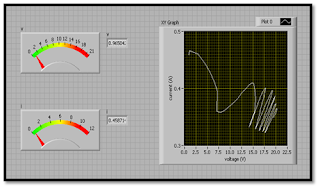

Figure 2: LabVIEW II

CONCLUSION

For this week, I have do the troubleshooting for my project to avoid the problems that can come out. Figure 1 shows the complete circuit and connections that is bridge rectifier circuit, current divider and voltage divider. When I conduct the troubleshoot, the graph still the same as before that is it opposite the actual graph. Firstly, I think it is because of the variable resistor and sir Zaki suggest I use more smaller value of variable resistor. So I change it it from 10kΩ to 5kΩ but there still the same output. So I change the variable resistor once more with 1kΩ and the graf change little. The graph become decline but there are so many noise. I try reduce it by doing again the connection between circuit but the result still the same. May be it because of the clip, connection or so on, I don't so sure. The connection from DAQ to desktop also can cause problem since sometimes it loose. May be cause by the crocodile clip since my friend say that her friend buy crocodile almost like me and have some doesn't function accordingly.

Friday, 12 April 2013

v0ltAge DiviDer and cUrrEnt DiviDer

OBJECTIVE

METHOD

RESULT

For the manual test, the graph become as exactly but when try it with the LabVIEW, there are some problems when the graph doesn't come out as the actual. The graph become opposite of the actual graph. The input from PV is separate into two that is current and voltage but the graph of both is combine (IV curve) to see the performance. But the LabVIEW only can accept 10v for voltage and 58mA for current. Since the output from PV is 21v for voltage and 0.4mA for current, it is a little high for LabVIEW to accept. So, the voltage divider and current divider being use to control the output from PV to become small enough for LabVIEW to accept. The voltage divider will divide the output from PV into 2, so the input into LabVIEW will become 10v and it exactly the amount that LabVIEW can accept. For that, 1kΩ is used. The current is used 6 resistor of 82Ω that connected in parallel to make sure the input is 50mA since the maximum current is 58mA. When test the circuit with LabVIEW, it worked but the graph is still not the actual graph.

- To improve the IV curve characteristic

- To testing the circuit and get the output produce from PV module

METHOD

- Firstly, test the circuit if it can produce the amount that I want

- Then, connect the circuit to the LabVIEW and observe the graph

Figure 1: Voltage Divider and Current Divider

Figure 2: LabVIEW

Figure 3: Graph IV Curve

RESULT

For the manual test, the graph become as exactly but when try it with the LabVIEW, there are some problems when the graph doesn't come out as the actual. The graph become opposite of the actual graph. The input from PV is separate into two that is current and voltage but the graph of both is combine (IV curve) to see the performance. But the LabVIEW only can accept 10v for voltage and 58mA for current. Since the output from PV is 21v for voltage and 0.4mA for current, it is a little high for LabVIEW to accept. So, the voltage divider and current divider being use to control the output from PV to become small enough for LabVIEW to accept. The voltage divider will divide the output from PV into 2, so the input into LabVIEW will become 10v and it exactly the amount that LabVIEW can accept. For that, 1kΩ is used. The current is used 6 resistor of 82Ω that connected in parallel to make sure the input is 50mA since the maximum current is 58mA. When test the circuit with LabVIEW, it worked but the graph is still not the actual graph.

Saturday, 6 April 2013

aChIng

OBJECTIVE

RESULT

- To expose student about aching

- To give understand more about project

METHOD

- Draw the circuit

- Apply the circuit in PCB layout

- Draw the PCB layout using PCB pen

- Put the circuit into the acid aching until only circuit drawing that left

- Remove the PCB pen using toner until the cooper that left and DONE

RESULT

CONCLUSION

This step is the simple way to do the aching. There are also other way that have to use UV printed and then aching. This UV is little difficult since the connection is easy to cut when it small. This aching is easy and can just do it at room. After finish aching, I have to drill a hole for placing components at the circuit.

Sunday, 31 March 2013

TeStiNg PV m0duLe

OBJECTIVE

RESULT

- To estimate the IV curve characteristics of PV module

- To estimate the power curve characteristics of PV module

METHOD

- Firstly, I have to construct the circuit as given in the experiment sheet

- The solar have to face the fake solar perpendicularly

- Then, get the readings of voltage and current by using varying the variable resistor (10k ohm)

- Next, the readings is recorded in Table 4.3

- Lastly, plot the graf

RESULT

CONCLUSION

From the graph, it shows the IV curve of photovoltaic. This experiment being conduct under ambient

temperature, 31oC. This

reading being measured by using multimeter. For conduct this experiment, fake

solar had been used to replace the sun to get a continuously reading. The

result is influence by the variable resistor since the setting of the variable

resistor is changes. When doing this experiment, I have to careful varying the variable resistor since it easy to damage if the input is high.

Saturday, 23 March 2013

Pr0t0tyPe

OBJECTIVE

RESULT

- To build a project prototype

METHOD

- Firstly, prepare all the equipment that are needed

- Build the prototype

RESULT

CONCLUSION

When doing this prototype, it take a few days when suddenly not enough equipment to complete it. I have to go to the hardware shop for twice. Finally, here the prototype.

Wednesday, 13 March 2013

tHerMal pAstE

OBJECTIVE

- To understand more about thermal paste

METHOD

- Find the information on the Internet

RESULT

Thermal paste, heat paste, heat sink paste or heat sink compound is a viscous fluid substance, originally with properties akin to grease, which increases the thermal conductivity

of a thermal interface by filling microscopic air-gaps present due to

the imperfectly flat and smooth surfaces of the components; the compound

has far greater thermal conductivity than air (but far less than

metal). In electronics, it is often used to aid a component's thermal dissipation via a heat sink....

Thermal conductor types:

Thermal greases use one or more different thermally conductive substances:- Ceramic-based thermal grease has generally good thermal conductivity and is usually composed of a ceramic powder suspended in a liquid or gelatinous silicone compound, which may be described as 'silicone paste' or 'silicone thermal compound'. The most commonly used ceramics and their thermal conductivities (in units of W/(m ·K)) are: beryllium oxide (218), aluminum nitride (170), aluminum oxide (39), zinc oxide (21), and silicon dioxide (1). Thermal grease is usually white in colour since these ceramics are all white in powder form. These figures are for bulk material, not thermal grease.

- Metal-based thermal grease contain solid metal particles (usually silver or aluminum). It has a better thermal conductivity and is more expensive than ceramic-based grease.

- Carbon based. There are products based on with carbon-based conductors, using diamond powder, or short carbon fibers, they have the best thermal conductivity and are generally more expensive than metal-based thermal grease.

- Liquid metal based. Some thermal pastes are made of liquid metal alloys of gallium. These are rare and expensive.

- Phase Change Metal Alloy (PCMA) is not a "grease" but another type of Thermal interface material. The design consists of a sealed alloy metal pad that needs to be "reflowed" under high heat (typically 90-100C.) The alloy on the inside of the seal will change phases, and fill all the micro-voids. Since this material is made of mostly metal alloy, the thermal properties of this interface material are very good.

All but the last classification of compound usually use silicone grease as a medium, a heat conductor in itself, though some manufacturers prefer use of fractions of mineral oil.All these compounds conduct heat far better than air, but far worse

than metal. They are intended to fill gaps that would otherwise hold

air, not to create a layer between component and heatsink—this will

decrease the effectiveness of the heatsink. Ideally perfectly smooth and

flat metallic surfaces would not need heatsink compound.

Thermal grease is primarily used in the electronics and computer industries to assist a heat sink to draw heat away from a semiconductor component such as an integrated circuit or transistor.

Thermally conductive paste improves the efficiency of a heatsink by

filling air gaps that occur when the imperfectly flat and smooth surface

of a heat generating component is pressed against the similar surface

of a heatsink, air being approximately 8000 times less efficient at

conducting heat than, for example, aluminum (a common heatsink

material).

Surface imperfections and departure from perfect flatness inherently

arise from limitations in manufacturing technology and range in size

from visible and tactile flaws such as machining marks or casting

irregularities to sub-microscopic ones not visible to the naked eye. Thermal conductivity

and "conformability" (i.e., the ability of the material to conform to

irregular surfaces) are the important characteristics of thermal grease.

Both high-power handling transistors, such as those in an audio amplifier, and high-speed integrated circuits, such as the central processing unit

(CPU) of a personal computer, generate sufficient heat to benefit from

the use of thermal grease to improve the effectiveness of a heatsink.

The need for heatsink compound can be minimised or removed by lapping the surfaces of the hot component and the matching heatsink face so that they are virtually perfectly flat and mirror-smooth.[citation needed] Computer overclockers,

who increase computer speed by measures which increase heat production,

resort to lapping and other extreme cooling methods such as water-cooling.

Application and Removal:

Computer processor heatsinks utilize a variety of designs to promote

better thermal transfer between components. Some thermal greases have a

durability up to at least 8 years.

Flat and smooth surfaces may use a small line method to apply material,

and exposed heat-pipe surfaces will be best prepared with multiple

lines.

Excess grease separating the metal surfaces more than the minimum

necessary to exclude air gaps will only degrade conductivity, increasing

the risk of overheating.

Silver-based thermal grease can also be either slightly electrically

conductive or capacitive; if some flows onto the circuits it can cause

malfunctioning and damage.

Over time, some thermal greases may dry out, have reduced heat

transferring capabilities, or set like glue and make it difficult to

remove the heat sink. If too much force is applied the processor may be

damaged. Heating the grease by turning the processor on for a short

period often softens the adhesion. It is recommended that thermal grease

be re-applied with each removal of the heatsink.

Silicone oil-based thermal grease can be removed from a component or heatsink with an alcohol (such as rubbing alcohol) or acetone. Special-purpose cleaners are made for removing heatsink grease and cleaning the surfaces.

Measurement tools allow to determine exactly the height of applied thermal grease.

or can visit this site to know more.....

to apply thermal paste: http://www.wikihow.com/Apply-Thermal-Paste

removal: http://www.techpowerup.com/articles/overclocking/134

Subscribe to:

Comments (Atom)